The global manufacturing landscape has undergone significant transformations in recent decades due to technological advancements, climate change, and geopolitical tensions. Concepts like Industry 4.0, incorporating the industrial internet of things and ‘smart’ manufacturing, have emerged as key frameworks to understand the various ways technological innovation has impacted manufacturing processes.

As the manufacturing sector continues its dynamic evolution, staying at the forefront is crucial. Explore the upcoming trends set to define the future of manufacturing in 2024.

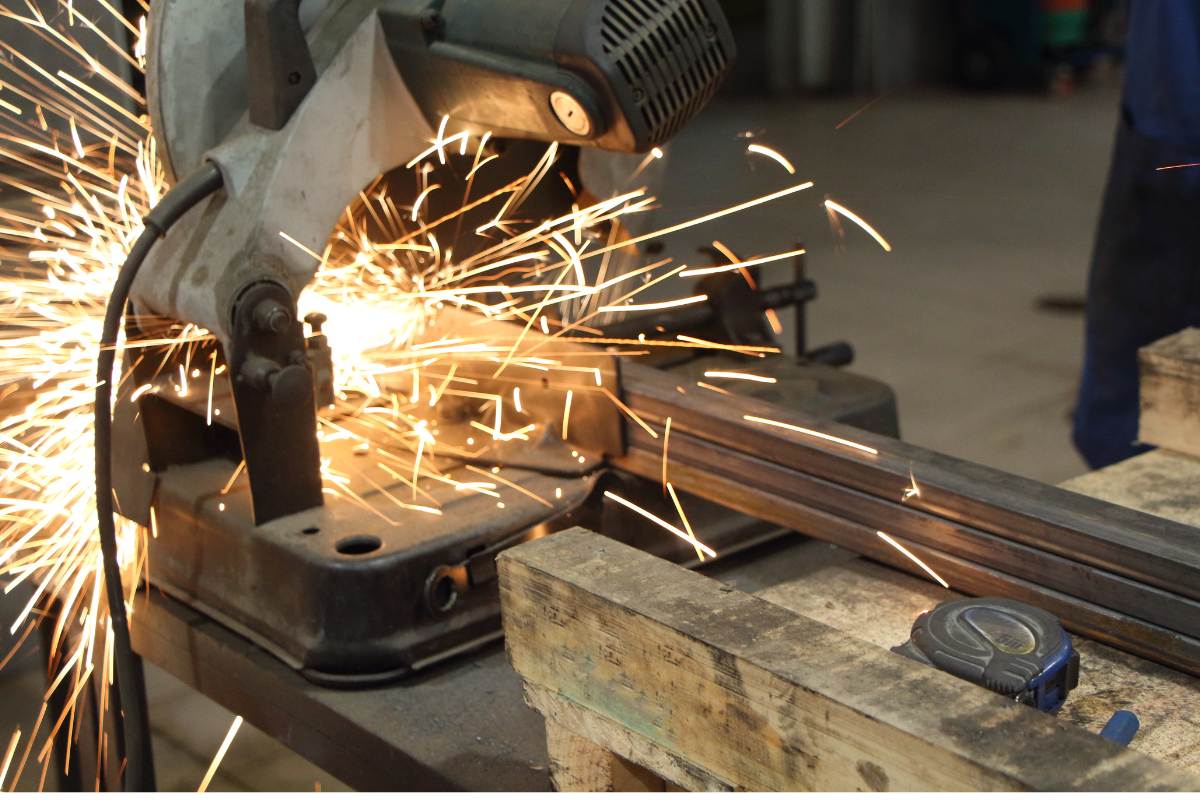

1. Industrial Automation

The realm of automation is poised for further expansion throughout manufacturing processes, featuring robots and cobots to enhance productivity and precision. Beyond traditional robotics, advanced automation will integrate AI for intelligent decision-making processes. This evolution promises more autonomous and self-regulating manufacturing systems, marking a significant leap forward in manufacturing efficiency.

2. Industrial Internet of Things (IIoT)

Increased connectivity through IIoT devices is poised to revolutionize decision-making with access to real-time data. This transformation will enhance asset management and predictive maintenance capabilities. The ripple effect of IIoT extends to creating more interconnected and intelligent supply chains, fostering cohesive and transparent operations through the integration of data from various manufacturing stages.

3. Sensors and Connectivity

The integration of more sensors and IoT devices into manufacturing equipment is set to revolutionize data collection and analysis, paving the way for superior process control and optimization. The advancements in sensor technology and connectivity will give rise to the development of ‘smart products.’ These products will provide data throughout their lifecycle, from the manufacturing stage to end-user interaction, fostering continuous improvement and innovation.

4. Cloud Computing

Manufacturers are embracing a shift to the cloud, facilitating remote monitoring and data analysis. This transition enhances flexibility and scalability, marking a significant evolution in manufacturing operations. Cloud-based solutions not only pave the way for remote capabilities but also enable collaborative and distributed manufacturing models. Examples include virtual factories, fostering resources and capability sharing across different locations.

5. Digital Twins

In 2024, the use of digital twins—virtual replicas mirroring physical manufacturing systems—will experience a significant surge. These digital simulations go beyond real-time monitoring, offering opportunities for optimization and efficiency enhancement, ultimately reducing downtime. Moreover, the evolving landscape will see digital twins playing a pivotal role in advanced scenario planning and troubleshooting. Manufacturers can simulate and predict the impacts of operational changes and external factors on their systems, marking a transformative leap in manufacturing capabilities.

6. Reshoring Strategies

With a spotlight on supply chain resilience, manufacturers are actively reshoring production to their home countries. This strategic shift aims not only to reduce dependency on foreign suppliers and alleviate supply chain disruptions but also to foster more localized, responsive, and sustainable manufacturing ecosystems. The result is a comprehensive approach that contributes to innovation and elevates quality standards within local industries.

7. Artificial Intelligence (AI)

AI-driven analytics is set to revolutionize manufacturing processes, optimizing production lines, predicting maintenance needs, and elevating quality control. This technological advancement becomes a pivotal enabler of efficiency, extending its impact to areas like supply chain optimization, demand forecasting, and human-robot collaboration. The result is a more responsive and seamlessly integrated production landscape.

8. Workforce Reskilling

To keep pace with technological advancements, manufacturers are making substantial investments in reskilling their workforce. Tailored training programs are focusing on digital skills, automation, and data analysis. These initiatives prioritize interdisciplinary skills, blending traditional manufacturing knowledge with essential digital proficiency. This transformative shift is designed to create a more agile and adaptable workforce, capable of harnessing the potential of advanced manufacturing technologies.

9. Carbon Neutrality & Environmental Sustainability

Environmental sustainability takes center stage as manufacturers intensify efforts to attain carbon neutrality. This commitment involves the implementation of green manufacturing processes and a concerted effort to reduce emissions. The journey towards carbon neutrality is anticipated to emphasize energy-efficient practices, integration of renewable energy sources, and advancements in material science. A holistic sustainability approach will be adopted, considering the entire lifecycle of products.

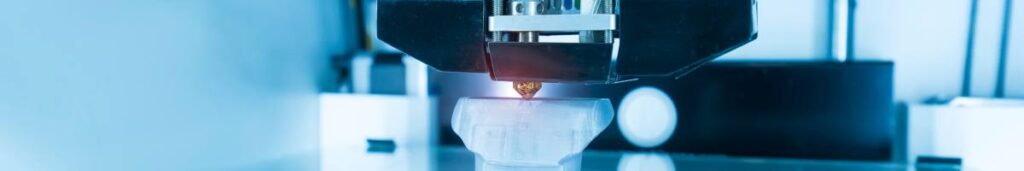

10. Additive Manufacturing

The integration of 3D printing and additive manufacturing is set to play an increasingly central role in the production process. This transformative technology facilitates rapid prototyping, customization, and minimizes waste. Anticipated advancements include the capability to handle a diverse range of materials, from advanced composites to biodegradable substances. This evolution opens exciting possibilities for sustainable manufacturing practices and the realization of intricate product designs.

In addition to these trends, the manufacturing sector is also focusing on:

- Digital Optimization Tools: Digital tools, including cloud computing and automation, will be increasingly used for real-time insights and optimizing production.

- Targeted Digitization: Focusing on specific production areas with digital tools can address common issues and improve overall efficiency.

- Human-Automation Interaction: Increased collaboration between workers and digital tools will enhance worker productivity and foster human-robot collaborations.

- Predictive Mindset in Maintenance: Shifting to predictive maintenance will be essential, with service engineers developing skills in data analytics and remote consultation.

The manufacturing industry in 2024 is set to continue its rapid evolution, with digital transformation, sustainability efforts, and workforce development as key drivers. These prevailing trends will redefine manufacturing processes and chart the course for the industry’s future.

Sources

10 Manufacturing Trends for 2024: Shaping the Future of Industry

The future of manufacturing: 5 key trends for 2024